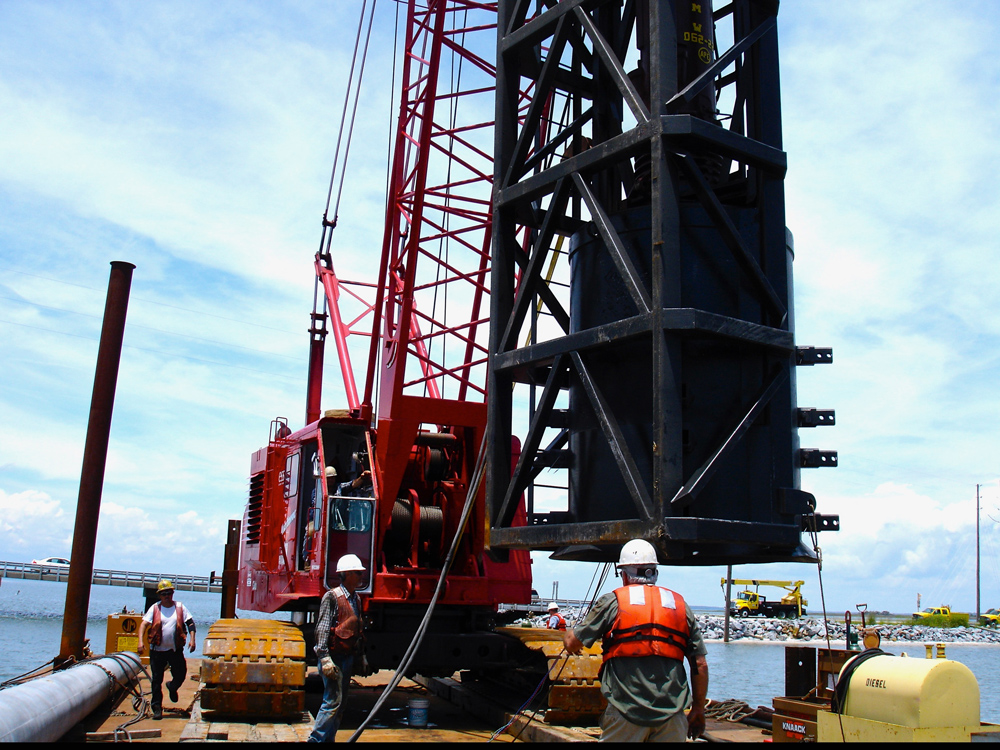

We were tasked to repair the structural framing inside of innerbottom fuel tanks, including under 550-ton steam engines, on a floating 100-year old battleship. We developed a thorough, engineered plan to re-frame the ship while it remained afloat. We cleaned the fuel tanks, suspended heavy components (550-ton steam engines), removed interreferences and tank tops in a sequence designed to prevent hull overstressing, added new transverse and longitudinal framing along with doubling up the keel to the existing structure. We tested each weld, coated all new steel, and welded new tank tops onto the tanks. These repairs make Battleship Texas ready to enter dry dock with much less risk of hull damage or collapse.